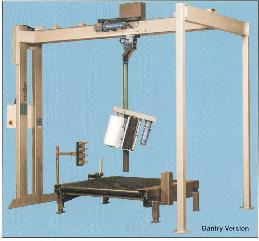

Muller Cobra 1525

Cobra 1525CN (CoNveyorized automatic)

This is Muller's conventional Rotary Tower Automatic stretch

wrapper. The unique rotating arm of the Cobra 1525 represents

yet another way (vs Octopus) to effectively wrap loads without

spinning them on a turntable. This method of wrapping is

especially useful when wrapping light loads, fragile loads,

or any load which might fall apart if spun on a turntable.

The Cobra 1525 is available in a wide range of prices and

capabilities and offers several options to meet even the

most challenging stretch packaging operations.

Featuring the same SG3000

Film Carriage and Cut/Seal

technology as its bigger automatic brothers (the Octopus),

this economical system can suit the needs of a lower

throughput application.

Cobra 1525CN specifications: click

here for a Machine Brochure (pdf).

Click here for comparison

charts to help you find a Conventional Stretch

Wrapper model to suit your needs and budget.

|

|

|

|

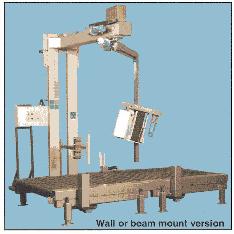

Cobra 1525A

This floor level (0" [zero] pass height) version of

the Rotary Tower Automatic stretch wrapper is purposefully

designed for a warehouse environment where hand trucks,

powered walkies, or forktrucks are all in use. In

comparison to standard semi-automatic stretch wrappers,

efficiency is improved and cycle time reduced by negating

the need for the operator to initially attach the

film and, upon completion of the cycle, stop to cut

and wipe down (seal) the film tail to the load. An

added benefit is the fact the film tail is heat

sealed to the load rather than a simple "tuck

under" or "wipe down" seal by the operator.

Cobra 1525A (Automatic) specifications: click

here for a Machine Brochure (pdf).

Click here for comparison

charts to help you find a Conventional Stretch

Wrapper model to suit your needs and budget.

|

|

|

The Cobra 1525 family functionally replaces

former models:

RTA, XTA, Multee Auto, 205, 230, Cobra 1500, Cobra XL, Cobra V,

King Cobra, Ultra XL, Ultra KL and Ultra VI.

|

Please Note: The above specifications

do not represent all options available for these machine.

Please contact us for more information.

|

|

|

Reconditioned Stretch Wrappers,

Priced to Sell with Attractive Deliveries

In

this time of economic uncertainty, spend your capital equipment budget

wisely with great deals on WARRANTIED Reconditioned

Stretch Wrappers, Conveyors, and other associated equipment. In

this time of economic uncertainty, spend your capital equipment budget

wisely with great deals on WARRANTIED Reconditioned

Stretch Wrappers, Conveyors, and other associated equipment. See our Used and Reconditioned Stretch Wrapping

Equipment page for details on our current offering.

See our Used and Reconditioned Stretch Wrapping

Equipment page for details on our current offering.

From low volume/low cost turntable semi-automatics, through turntable

and rotary tower fully automatic systems, to the economical Octopus 202,

and right on up to a high speed/high volume/highly efficient Octopus 606/808, we have a reconditioned stretch wrap machine to suit your needs.

we have a reconditioned stretch wrap machine to suit your needs.

Where

capital funds and/or delivery expectations are an issue, let GAP's reconditioned

stock machines fill your need. Where

capital funds and/or delivery expectations are an issue, let GAP's reconditioned

stock machines fill your need.

Contact Us for details.

|

|