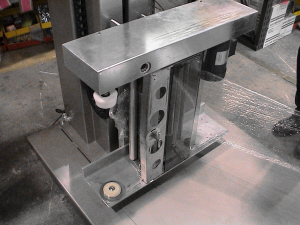

Muller SG3000 Film Carriage

An

evolutionary advancement in the state-of-the-art stretch

wrapping technology, the technology long used for all Octopus

stretch wrapper ST2000 Film Carriages has been ported over

for use on all models and styles of stretch wrapping machines.

The new SG3000 Film Carriage retains the benefit of strain

gauge technology (long present in all Muller higher end

semi-auto and automatic stretch wrapping systems) while

adding the ease of loading and safety features previously

only available on the Octopus' ST2000 Film Carriage . The

SG3000 Film Carriage is also available as an easy to install

retrofit to your existing equipment, there is no reason

your stretch wrapping systems can't take andvantage of the

best the industry has to offer! This film carriage is now the standard on

most conventional pallet stretch wrapping machines throughout

the Muller line. This carriage has demonstrable superiority

over older and competitor designs. The primary advantages

of the design are reliability, ease of film loading, long

term consistency of prestretch levels, and stretchwrap film

savings.

|

|

Ease

of Film Loading Ease

of Film Loading

Changing the film roll is easier and faster

due to the front mounted film threading gate, which allows

the operator to safely pull film through the 20" carriage

without having to thread the film manually. Film threading

through the prestretch rollers is easier and faster due

to the plexiglass gate with safety switch which allows

the operator to pull film through and close the gate for

automatic threading. This is a vast improvement over previous

designs which required the operators to thread the film

through the actual prestretch rollers while manually rotating

the rollers by hand.

Reliability of Operation

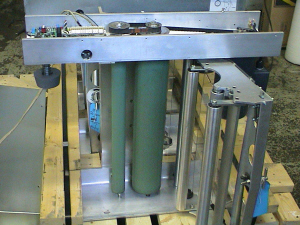

The patented Strain Gauge Film Force control

with analog feedback is an  electronic

film feed tension-sensing system designed to greatly optimize

film tension, thus reducing the chance of broken film. Reliability

is further enhanced through the tried and true engineering

principle of eliminating moving parts. Older and competitor

designs use a spring-mounted pivoting dancer roller arm

(often called a 'dancer bar') to sense and accommodate the

variable film feed rates required by irregularly shaped

loads. The SG3000's patented electronic film feed tension

sensing system eliminates the need for a moving dancer bar

assembly. This design has proven itself to very reliable,

reducing maintenance costs, and valuable downtime. At the

same time, this zero inertia fixed-mount roller provides

a faster response to load irregularities, automatically

adjusting the film delivery speed to keep a constant film

force-to-load regardless of load position, size, or shape. electronic

film feed tension-sensing system designed to greatly optimize

film tension, thus reducing the chance of broken film. Reliability

is further enhanced through the tried and true engineering

principle of eliminating moving parts. Older and competitor

designs use a spring-mounted pivoting dancer roller arm

(often called a 'dancer bar') to sense and accommodate the

variable film feed rates required by irregularly shaped

loads. The SG3000's patented electronic film feed tension

sensing system eliminates the need for a moving dancer bar

assembly. This design has proven itself to very reliable,

reducing maintenance costs, and valuable downtime. At the

same time, this zero inertia fixed-mount roller provides

a faster response to load irregularities, automatically

adjusting the film delivery speed to keep a constant film

force-to-load regardless of load position, size, or shape.

|

Stretchwrap

Film Savings Stretchwrap

Film Savings

With the analog feedback greatly optimizing

film tension, it is possible for you to either increase

the prestretch level, or convert to a lower gauge film.

In many instances, customers have had no problem accomplishing

both! So with a higher prestretch and/or a lower gauge film,

and increased reliability reducin g

unwanted downtime and maintenance costs, you can wrap more

loads, with a more consistent film tension, all while using

less film. It's money in the bank! g

unwanted downtime and maintenance costs, you can wrap more

loads, with a more consistent film tension, all while using

less film. It's money in the bank!

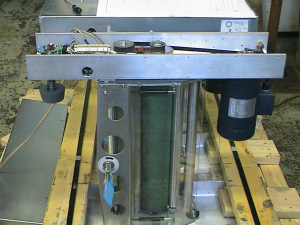

Long Term Consistency of Prestretch Levels

The primary problem with any prestretch

carriage is that as the springs in the tension rollers

grow weak and the pre-stretch rollers wear down with long

term use, the film will have a tendency to pull through

the prestretch carriage without stretching the film. It

will simply slip through. To combat this, the Muller SG3000

has the film path arranged in such a way that the film

wraps around the circumference of the prestretch rollers

to the maximum extent possible. The end result is a consistently

higher prestretch level over the long term.

Safety Safety

The totally enclosed pre-stretching mechanism

can only be accessed (for changing of the film or maintenance)

through an electrically interlocked door. There is no

way for operators or maintenance personnel to access the

rollers without the power to this device being disabled,

even if they forgot to de-energize the machine as per

standard operating procedures and posted notices. This

design commonly satisfies all Pre-Start Safety Review

(PSR) concerns.

|

|

Standard Specifications

- 1/2 HP 90V DC Variable Speed motor/reducer, high quality Dart

DC/SCR controller.

- Electronic strain gauge tension roller replaces the spring-mounted

pivoting dancer roller arm.

- Zero inertia fixed-mount roller reduces maintenance while

the faster response design adjusts the film delivery speed to

keep a constant film force-to-load regardless of load position,

size or shape.

- Spring-loaded pressure roller offers a maintenance-free, continuously

self-adjusting design to prevent film slippage, inconsistent

stretch levels, and excessive film wrapping costs.

- Lubrication-free direct gearing prestretch ratio control eliminates

conventional chains, sprockets and take-up idlers for virtually

maintenance-free operation.

- The lowest film web neckdown of any powered film prestretch

carriage in the industry.

- The SG3000-20" will handle films from 0.4 mil to 1.35 mil

and prestretch ratios up to 400%.

|

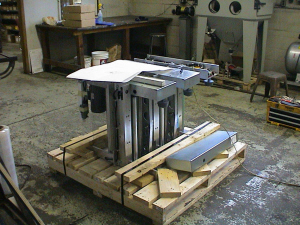

SG3000 Film Carriage Retrofit

|

Specifically designed to easily retrofit

onto any conventional stretch wrapper design, semi-auto

or automatic, turntable or rotary arm style machine, the

advantages of the SG3000 can be realized in your application.

GAP skilled and knowledgable Installation Technicians can

retrofit this product onto your equipment.

|

The scope of work required to accomplish the installation of

the SG3000 retrofit requires (but is not limited to) the following:

- Mechanically, and electrically remove the existing Film Carriage,

replacing it with the quoted model SG3000

- Includes necessary engineering and production of a customized

Retrofit Technical Manual.

- Includes necessary PLC program changes and optimizations to

the wrap cycle.

- Includes system power up check; run and production testing.

- Also included is the time for one GAP technician to be present

for the production startup, to address any issues that may arise

when running actual product, and to provide training to your

operators and maintenance staff.

- INSTALLATION NOTE: - This project is likely to require some

cutting, welding, grinding, etc. Use of your fabrication facilities

and/or the assistance of your plant personnel should be expected.

|

|

|

|